Gel strength definition

Gel strength definition refers to the quantitative measurement of a gel’s resistance to deformation or rupture under an applied force. In practical terms, it describes how firm, elastic, or resilient a gel structure is when subjected to compression or penetration. This property plays a decisive role in industries such as pharmaceuticals, food, medical materials, and packaging, where gelatin and other hydrocolloid gels must deliver consistent mechanical performance.

Understanding the gel strength definition allows quality professionals to control formulation stability, predict product performance, and ensure compliance with relevant standards. Instead of being an abstract concept, gel strength links material science directly with real-world functionality, such as capsule integrity, food texture, or biomedical material reliability.

What is gelatin strength

To fully grasp the gel strength definition, it is essential to clarify what is gelatin strength. Gelatin strength describes the force required to deform a standardized gelatin gel to a specified depth under controlled conditions. It reflects the molecular network formed during gelation and indicates the quality and consistency of gelatin.

Higher gelatin strength generally correlates with a stronger, more elastic gel network, while lower values suggest a softer structure. In pharmaceutical capsules, gelatin strength affects shell robustness and dissolution behavior. In food applications, it influences mouthfeel and product stability. As a result, gelatin strength becomes a key quality parameter rather than a simple laboratory value.

Gel strength tester

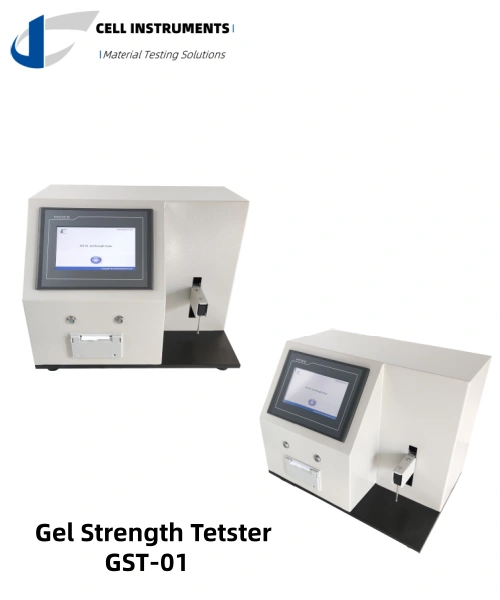

一个 凝胶强度测定仪 serves as the primary instrument for evaluating gel strength definition in a repeatable and standardized manner. The tester applies a controlled force to the gel sample through a probe, measuring the resistance encountered during deformation. This direct mechanical interaction provides precise and objective data.

Modern gel strength testers integrate load cells, displacement sensors, and digital control systems. These components ensure accuracy, repeatability, and compliance with international testing practices. For laboratories that handle frequent gelatin or hydrogel testing, reliable instrumentation reduces variability and improves confidence in reported results.

Cell Instruments offers the GST-01凝胶强度测定仪, designed to support professional gel strength evaluation across pharmaceutical, food, and material testing environments. Its configuration allows users to align testing conditions with established standards while maintaining operational efficiency.

纹理分析

纹理分析 represents the broader scientific framework within which gel strength definition is evaluated. Rather than focusing on a single force value, texture analysis examines how materials respond to mechanical stress, including compression, penetration, and recovery behaviors.

In gel testing, texture analysis links numerical gel strength values to sensory and functional properties. For example, a gel with adequate strength but poor elasticity may fail in practical use. By integrating texture analysis concepts, laboratories gain deeper insight into gel performance beyond pass–fail criteria.

Texture analysis principles also support method development and customization. When standard test conditions do not fully represent real application scenarios, parameters such as probe geometry, speed, and compression depth can be adjusted in a controlled manner.

Testing methods and standards related to gel strength

The gel strength definition gains authority through standardized testing methods. Industry-recognized procedures specify sample preparation, conditioning temperature, probe dimensions, and test speed to ensure comparability of results.

Guidelines referenced in documents such as PSTC16 emphasize consistent methodology, proper calibration, and statistical validation. These practices enhance test credibility and reduce inter-laboratory variation. By following such frameworks, quality teams ensure that gel strength data supports regulatory submissions, supplier qualification, and internal quality control.

Although different industries may adopt customized conditions, adherence to recognized standards remains essential. Standard-based testing strengthens data reliability and supports global communication of quality metrics.

Practical significance for quality control and product development

Applying the gel strength definition in routine testing supports both quality assurance and product innovation. In pharmaceutical production, consistent gel strength ensures capsule durability and predictable dissolution. In food processing, it supports texture consistency and consumer acceptance. In medical and packaging materials, it contributes to safety and performance reliability.

By selecting appropriate testing methods and instruments, laboratories can detect formulation changes early, reduce waste, and improve batch-to-batch consistency. Instruments such as the GST-01凝胶强度测定仪 from Cell Instruments help integrate gel strength testing into broader quality systems without unnecessary complexity.

Choosing the right solution for gel strength testing

An effective approach to gel strength definition requires more than a single measurement. It combines sound understanding, standardized methodology, and dependable instrumentation. Cell Instruments focuses on providing testing solutions that align with professional expectations while allowing flexibility for specialized applications.

With expertise spanning packaging, pharmaceutical, medical, and material testing, Cell Instruments supports customers not only with equipment but also with technical exchange, customization, and automation options. This comprehensive approach helps laboratories translate gel strength data into meaningful quality decisions.

In summary, the gel strength definition represents a foundational concept in material and product performance evaluation. Through proper understanding, standardized testing, and advanced texture analysis, professionals can ensure that gel-based products meet functional and regulatory demands with confidence.